charpy impact test ansys|Experiment 7: Charpy Impact Test : online sales The aim of this paper is to report the analysis of Vehicle anti-roll bars (stabilizer bars)used for suspension components limiting body roll angle using the finite element analysis tool ANSYS. Resultado da The following links provide information and technical guidance for Software Developers and Transmitters who are interested in developing software for .

{plog:ftitle_list}

14 de jul. de 2023 · Se referindo em nomes para duo, separamos os mais legais, engraçados e criativos nicks do Free Fire. Nome para Duo no Free Fire. TonyStark / .

The aim of this paper is to report the analysis of Vehicle anti-roll bars (stabilizer bars)used for suspension components limiting body roll angle using the finite element analysis tool ANSYS. This FEA case can be solved in the following versions: ANSYS 14, ANSYS 14.5, ANSYS 14.5.7, ANSYS 15, ANSYS 16, ANSYS 16.1, ANSYS 16.2, ANSYS 17, ANSYS 17.1, ANSYS 17.2, ANSYS.

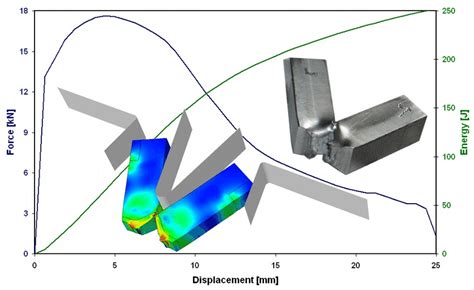

This paper presents the results of Charpy impact test on Mild steel as measured impact force time history. A detailed Finite Element model of the Charpy impact test specimen is . Charpy, impact, Izod impact, static structural analysis in ansys workbench, ansys workbench static structural tutorial pdf, ansys workbench examples, dynamic. If you are interested in building and performing similar scenarios, you can download their MECHDAT files to see the settings we used for materials, mesh, boundary conditions, loads, time steps.Objectives: To study the impact resistance of metals using impact testing machine of the Charpy type. To determine the variation of impact strength of a material with change in .

This paper describes nonlinear finite element analysis (FEA) to examine the energy to fracture unnotched Charpy specimens under pendulum impact loading. An oversized, nonstandard .

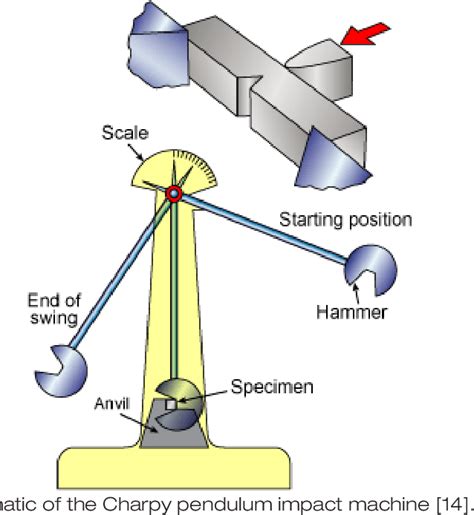

During the Charpy impact test standardized sample material is used to calculate material toughness under specific conditions i.e. mounting, notching and pendulum velocity at impact.

Charpy V-notch impact testing is widely used in the toughness assessment of large forged components, e.g. the pressure vessel for pressurised water reactors (PWR). At low temperature, A508 Cl.3 .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D .The modelling is based on representative volume element (RVE) micro-scale property homogenisation in ANSYS Workbench, followed by macroscale impact analysis in ABAQUS/EXPLICIT. The damage propagation was determined using the Hashin failure criteria. . The Charpy impact test results can only be used as comparative data to assess the impact .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The absorbed energy functions as an indicator of the material’s notch toughness.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation . One of the most prominent impact tests is the Charpy impact test that gives information regarding the behaviour of material under impact load [8], [9], [10]. Charpy test is a low-cost and reliable technique that measures the energy consumed in breaking a notched specimen simply supported at both ends when hammered by a swinging pendulum.

The Charpy impact test has been simulated based on the determined parameters combined with the trial algorithm method. According to the test results, the strain rate related damage parameter was deduced and the reliabilities of the FEM results were verified. Finally, based on the constitutive parameters and damage parameters of J-C model .and deformation paths in V-notch and Charpy impact tests for 340R 4 CHARPY IMPACT TEST The Charpy V-notch impact test was carried out based on KSB 0810-2003 to determine the impact performance of the three steel sheets. During the Charpy impact test, the maximum velocity of the falling pendulum is 5.4m/sec, which have a total kinetic energy of .

The Impact Testing Machine is very important for testing and calculating the impact energy required to bent or to break the different types of materials by conducting Charpy and Izod test. The aim of the project is to model, Assemble, Drafting and analyze the parts of Impact Testing Machine. 3-dimensional model of impact testing machine is createdsignificance of fracture toughness or CVN impact energy in a structure without a pre-existing crack is unclear. Pendulum impact testing, such as the standard CVN test, has been used to examine the impact resistance of materials for over a century because it is relatively simple, inexpensive, and rapid to perform [3].

Simulation of a Charpy V

One of the most prominent impact tests is the Charpy impact test that gives information regarding the behaviour of material under impact load [8], [9], [10]. Charpy test is a low-cost and reliable technique that measures the energy consumed in breaking a notched specimen simply supported at both ends when hammered by a swinging pendulum. For more info on charpy test or to download the keyword files please visit www.feasolution.blogspot.comChapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Visit https://www.letusresearch.com to post your queries and have a discussion from people all around the world working on that topic.finite element analysis.The Charpy test has been the most widely used test for a century to indirectly and cost-effectively assess the toughness and ductile fracture properties of X80 steel, as well as to evaluate their strength. A very thorough study has been highlighted on investigating the effects of various factors on the Charpy impact test of X80 steel.element code (ANSYS/LS-DYNA) and the experimental tests are formed by quasi-static tests . (Charpy impact test and drop-test). Quasi-static tests are used to estimate material properties of laminate in tensile, compression and flexure. The Charpy impact test is used to calibrate the material model implemented into finite element code2.6 Charpy impact test Impact tests are designed to measure the resistance to failure of a material to a suddenly applied force. The test measures the impact energy, or the energy absorbed prior to fracture. Charpy bar test pieces (12x6x50 mm3) were machined. Three specimens of each set were tested to ensure the repeatability from which the

The Charpy impact test is a basic mechanical test that is used to evaluate the toughness of materials and determine the crack fracture toughness of materials.The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen. For example, Figure 8(a) illustrates a simulated Charpy impact test and Figure 8(b) shows the corresponding experimental test specimen before and after impact. The simulation provides a deeper understanding of the fracture process and shows the maximum principal stress distribution of the MMC particles and matrix. . Ansys Explicit Dynamics .

charpy impact test shiny area

This tutorial demonstrates the Analysis of Reinforced Concrete Beam (RC Beam) | Charpy Test in Ansys Explicit Dynamics. All the steps are provided including . Charpy impact test is a low cost but reliable test that breaks a notch specimen under impact loading using a hammer, and evaluates the amount of energy consumed during breakage . Several researchers have focused their work, both experimental and numerical, in the area of impact testing to analyse different materials behavior. I am wanting to use a specific material which is G10. The material data I have access to is limited to the flexural strength, tensile strength and impact (notched charpy). Material datasheet is here - https://bit.ly/2IDt78o. I do not know how to enter the data I have access to into Ansys, if it is possible. Any help that can be given is .

The test is very much similar to the Charpy impact test but uses different type of specimens for testing. The Izod impact test differs from the Charpy impact test in that the test sample is held in a cantilevered beam configuration as opposed to a three-point bend configuration. Both notched and un-notched Izod Charpy impact test provide .

charpy impact test shutters

WEBEste site pode utilizar cookies para segurança e para lhe assegurar uma experiência otimizada. Você concorda com a utilização de cookies ao navegar neste ambiente?

charpy impact test ansys|Experiment 7: Charpy Impact Test